E-Waste - Gold Extracted From Electronic Waste

MINEWORX TECHNOLOGIES LTD - MWX TSX.V - MWXRF OTC

Corp Update Jan 10, 2018 - Latest Video

E-Waste - Future Of Urban Mining - News Letter - Streetwise Report

|

New Eco-Friendly Alternative

to Cyanide and Toxic Acids for Gold Extraction in E-Waste -

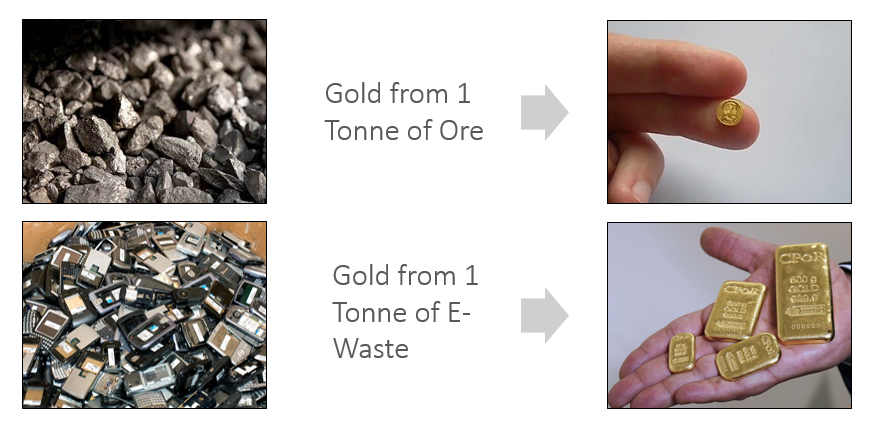

Mining Motherboards Mineworx Technologies is an Eco-Disruptive technology company providing gold processing solutions for both E-Waste and mining sectors Their flagship innovation is the patent-pending X-leach, an eco-friendly, safe, non-cyanide process for the extraction of precious metals in Electronic Waste (E-Waste) and mining sectors. Latest Video X-leach represents the single most promising alternative to toxic cyanide-based or hot acid-based leaching or smelting for the E-Waste sectors, a potentially multi-billion-dollar opportunity. E-Waste processing is a massive, growing sector which will readily adapt X-leach as a solution to the currently unsafe toxic methods of E-Waste precious metals extraction. Media Highlights Recently reaching their 52 week high of $0.38 CN these shares trade an average of 863,000 shares per day with 288 million shares outstanding .This company is executing its business model which we feel will serve its shareholders well. These shares are significantly undervalued . With a superior management team and business model in place , this company is positioned for growth through advanced E-waste opportunities utilizing its licensed cyanide-free precious metals extraction formula .  FACT SHEET - POWER POINT PRESENTATION - RESEARCH REPORT - MINING WEEKLY - E-SCRAP NEWS |

Mineworx Advances E-Waste Processing in Canada and the USA

BURNABY, British Columbia,

July 17, 2018 (GLOBE

NEWSWIRE) -- Mineworx

Technologies Ltd.,

(the "Company"

or "Mineworx")

(TSXV:MWX) (OTCQB:MWXRF)

(FSE:YRS) (WKN:A2DSW3) is

pleased to report that in

addition to the excellent

results reported by our

Joint Venture partner

EnviroLeach Technologies in

their news release of today

(click HERE to

view) that Mineworx has most

recently achieved the

following:

“These combined facilities will quadruple the capacity of Company’s E-Waste fabrication and production capabilities to almost 28,000 square feet,” Commented Greg Pendura, CEO. “This expansion now enables Mineworx to move quickly upon the site acceptance of the Memphis, Tennessee E-Waste processing plant to immediately expedite our business model in this dynamic sector.” To facilitate with the expansion and transition into a fully operational organization, the Company has hired Sarah Heath as the Manager of Human Resources, Health and Safety. Sarah brings multiple years of experience in these functions and will assist with the progression of the Mineworx/EnviroLeach JV as it moves into commercial production. About Mineworx

Mineworx is positioned for

growth through partnerships

with advanced mining and

E-Waste opportunities

utilizing its proprietary

and patent pending

extraction technologies.

These innovations will

increase and enhance

business opportunities by

deploying cost effective,

environmentally friendly

extractive metallurgy

solutions. This press release contains certain statements which constitute forward-looking statements or information (“forward-looking statements”), including statements regarding Mineworx’s business. Such forward-looking statements are subject to numerous risks and uncertainties, some of which are beyond Mineworx’s control, including the impact of general economic conditions, industry conditions, volatility of commodity prices, currency fluctuations, environmental risks, operational risks in exploration and development, competition from other industry participants, the lack of availability of qualified personnel or management, stock market volatility and the ability to access sufficient capital from internal and external sources. Although Mineworx believes that the expectations in the forward-looking statements are reasonable, they are based on factors and assumptions concerning future events which may prove to be inaccurate. Those factors and assumptions are based upon currently available information. Such statements are subject to known and unknown risks, uncertainties and other factors that could influence actual results or events and cause actual results or events to differ materially from those stated, anticipated or implied in the forward-looking information. As such, readers are cautioned not to place undue reliance on the forward-looking information, as no assurance can be provided as to future results, levels of activity or achievements. The forward-looking statements contained in this document are made as of the date of this document and, except as required by applicable law, Mineworx does not undertake any obligation to publicly update or to revise any of the included forward-looking statements, whether as a result of new information, future events or otherwise. The forward-looking statements contained in this document are expressly qualified by this cautionary statement. For further information, go to www.mineworx.net For further information contact:

MINEWORX TECHNOLOGIES LTD. Mineworx Announces Alliance With Murdock Capital Partners BURNABY, British Columbia, Jan. 18, 2018 (GLOBE NEWSWIRE) -- Mineworx Technologies Ltd. (the "Company" or "Mineworx") (TSXV:MWX) (OTCQB:MWXRF) (FSE:YRS) (WKN:A2DSW3) today announced a corporate advisory agreement with Murdock Capital Partners Corp., New York, NY. According to the terms of the agreement Murdock will act as a corporate market advisory consultant to Mineworx. “We look forward to working with them to broaden our presence in the United States through potential partnerships, direct contact with major listing exchanges, conference providers and industry experts,” commented Mineworx CEO Greg Pendura.

Since its inception, Murdock has assisted in listing nearly two dozen companies on major Exchanges, including the NYSE New Markets Exchange, the NYSE, NASDAQ, OTCQX, and Toronto Stock Exchange. Murdock handles all aspects of corporate market advisory, including the solicitation of industry experts, overviews of business related opportunities and financing transactions. It has conducted 27 conferences on specific natural resource and related technology innovations and opportunities, including recycling and precious metals recovery. About Mineworx Mineworx is positioned for growth through partnerships with advanced mining and E-Waste opportunities utilizing its proprietary and patent pending extraction technologies. These innovations will increase and enhance business opportunities by deploying cost effective, environmentally friendly extractive metallurgy solutions. About Murdock Capital Murdock Capital Partners Corp. (Murdock Capital) is a private merchant banking firm with 26 years of experience in advisory work with companies in the natural Technologies and energy-related industries. Murdock Capital acts as financial intermediary and/or principal for small and medium size companies and advises its corporate clients on all aspects of investment banking, including mergers and acquisitions, public and private financing, management buy-outs and corporate divestitures. The company’s knowledge and experience in assessing and formulating a corporate strategy includes marketing, strategic alliances and business management, all of which greatly increases the probability of clients’ success. Murdock Capital specializes in due diligence, market research, competitive analyses, financial and transaction structuring and corporate advisory services with the ultimate goal of always obtaining the desired results for their clients. EnviroLeach and Mineworx Provide Year End Corporate Update VANCOUVER, B.C., Jan. 10, 2018 (GLOBE NEWSWIRE) -- EnviroLeach Technologies Inc. (the "Company" or "EnviroLeach"), (CSE:ETI) (OTCQB:EVLLF), in conjunction with Mineworx Technologies (“Mineworx”), (TSXV:MWX), (OTCQB:MWXRF), are pleased to provide the following corporate Year-End update on their activities. 2017 was a pivotal year for both EnviroLeach and Mineworx. The companies successfully advanced their proven chemical formulas and mechanical processes with several additional proprietary and patent-pending breakthroughs. These new discoveries include significant enhancements to the proven EnviroLeach E-Waste process with respect to improved leach kinetics, improved recoveries, metal complex stability, element selectivity, metal precipitation and the reusability of the primary solution. EnviroLeach will continue to investigate additional applications of its formula to enhance its future offerings. The Company plans to expand its reach into the recoveries of strategic metals including lithium and cobalt from lithium ion batteries and the recovery of select rare earth elements. EnviroLeach and Mineworx completed a series of successful pilot scale tests throughout 2017 and completed the design and engineering and construction of the first production scale, 10 tonne per day E-Waste processing plant which was installed on-schedule and on-budget at the Memphis, Tennessee facility. Both EnviroLeach and MineWorx employees continue to work diligently at the Memphis location with full-scale trials expected to continue into late January 2018. The anticipated environmental footprint of this plant will be almost zero, with no water effluent, off-gassing or landfilled tailings. The plant will produce precious metals at a much-reduced carbon footprint to that of conventional mining. About the E-Waste Management Sector According to the Global E-Waste Monitor 2017, released by ITU, the UN University (UNU) and the International Solid Waste Association (ISWA), in 2016, 44.7 million metric tonnes of E-Waste were generated, an increase of 3.3 million metric tonnes, or 8 per cent, from 2014. Experts foresee e-waste increasing a further 17 per cent to 52.2 million metric tonnes by 2021. In 2016, only about 20 per cent, or 8.9 million metric tonnes, of all e-waste was recycled. Low recycling rates can have a negative economic impact. In 2016, it was estimated that e-waste contained rich deposits of gold, silver, copper, platinum, palladium and other high value recoverable materials, whose total value is estimated at $65 billion, a figure exceeding the gross domestic product of many countries in the world. Duane Nelson, EnviroLeach CEO, states, "According to Apple’s latest sustainability report, just 100,000 iPhone 6 devices contain, 1.3 kg Gold, 7 kg of silver, 0.4 kg platinum group metals, 550 kg cobalt and 800 kg of copper worth some $102,000 or approximately $7,900 per tonne. Compared to today’s conventional mining, where the world’s average current gold grade is worth some $43.00 per tonne, the financial metrics of urban-mining (E-Waste) are compelling." The Company also reports it has received inquiries from over 20 countries regarding potential partnerships on E-Waste processing plants world-wide. About the Mining Sector The hydrometallurgical extraction of gold from ores, concentrates, and tailings in a cost effective and environmentally safe manner offers an interesting challenge. Conventional gold mining operations rely heavily on cyanide leaching as the predominant method for recovering gold from ores and concentrates. Cyanide has been the leach reagent of choice in gold mining because of its high gold recoveries, robustness and relatively low cost. A recent study by SME (Society for Mining, Metallurgy and Exploration) indicates that over 76% of gold is produced using cyanide extraction. The gold mining sector uses approximately 66,000 tons of sodium cyanide worldwide. Although cyanide has been safely used on hundreds of mines worldwide, both the use, disposal and social implications of cyanide present significant safety, permitting and environmental risks. The EnviroLeach process provides a cost-effective alternative to cyanide offering similar or improved leach kinetics on most ores and concentrates (including ores that contain arsenic, copper, sulfides etc.). The reagent is environmentally-friendly, safe, stable, has a broad applicability spectrum making it an ideal alternative to cyanide in vat leaching operations worldwide. The Company has completed thousands of tests and assays on a variety of ores, concentrates and tailings with very positive results and continues to work with select mining companies to advance the chemistry and processes within this sector. To-date, EnviroLeach and Mineworx have received inquiries from over 100 mining companies in over 20 countries worldwide. About EnviroLeach Technologies Inc. EnviroLeach Technologies is a technology company and near-term gold producer that is engaged in the development and commercialization of environmentally-friendly formulas and technologies for the treatment of materials in the mining and E-Waste sectors. Using its proprietary non-cyanide, water-based, near neutral pH treatment process, EnviroLeach extracts precious metals from ores, concentrates, and E-Waste using only FDA approved additives to ambient temperature water. Backed by the momentum of a first-class staff of scientists and engineers, tens of thousands individual assays, independent validations and strategic partners, EnviroLeach’s technology will become the standard for the provision of eco-friendly methods for the hydrometallurgical extraction of precious metals in both the conventional mining and E-Waste sectors. Further information is available on the EnviroLeach web site: https://enviroleach.com About Mineworx Mineworx is positioned for growth through partnerships with advanced mining and E-Waste opportunities utilizing the EnviroLeach precious metals extraction process and patent-pending portable extraction technologies. These innovations will increase and enhance business opportunities by deploying cost effective, environmentally friendly extractive metallurgy solutions. Neither the TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in the policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release. Further information is available on the Mineworx web site: https://mineworx.net

|